CVMR CARBONYL PROCESS Application to Laterite Ore of a CVMR client in Africa

CVMR® CARBONYL PROCESS Application to Laterite Ore of a CVMR® client in Africa

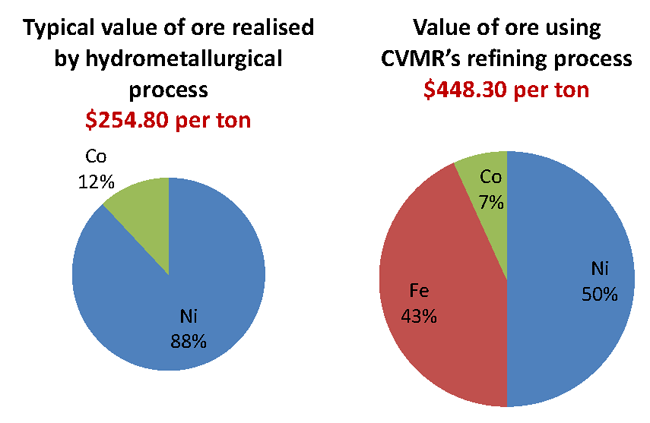

- CVMR®’s process for refining of Ferralite and Saprolite ore maximizes value of the ores by producing value added products.

Ferralite ore

- A typical Ferralite ore contains 40-45% of Iron, 1-1.5% of Nickel, 0.04-0.10% of Co (potentially Copper, PGE and Rare earth elements).

* Published with permission of the client.

Read also