PROCESS FOR RECOVERING METALS

Abstract:

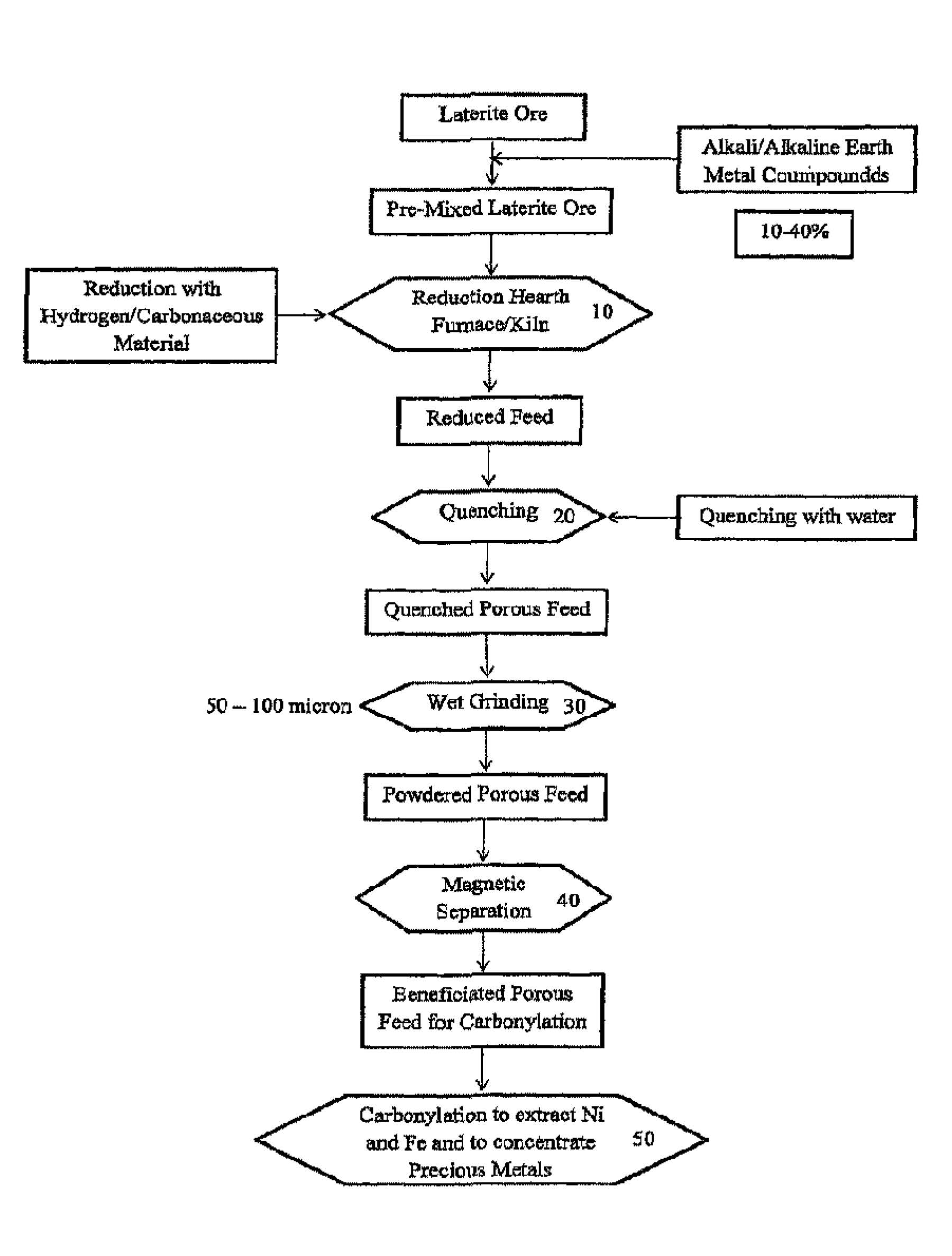

There is provided a process for treating a feed material comprising: contacting the feed material with a reducing agent within a contacting zone, wherein the feed material includes at least one operative metal-comprising compound, wherein each one of the at least one operative metal-comprising compound, independently, includes at least one operative metal species, wherein the operative metal of the operative metal species is one of nickel and iron, wherein the contacting is such that a reactive process is effected such that a solid intermediate product is produced, and such that a reaction mixture is disposed within the contacting zone and the reaction mixture includes the feed material, the reducing agent, and the solid intermediate product; wherein the reactive process is such that: for each one of the at least one operative metal-comprising compound, independently: for each one of the at least one operative metal species of the operative metal-comprising compound, independently, at least a fraction of the operative metal species of the operative metal- comprising compound is reduced such that the elemental form of the operative metal is produced; such that the solid intermediate product includes the produced elemental form of at least one of nickel and iron; quenching the reaction mixture; converting at least a fraction of the solid intermediate product to a gaseous intermediate product; and fractionating the gaseous intermediate product such that at least one operative metal-rich product is produced.

Read also