Surface Engineering by the Carbonyl Process

Table of contents

Surface Engineering by the Carbonyl Process

Problem:

The DoD spends tens of billions of dollars each year on corrosion & wear prevention and repair. Many technologies are employed for different alloys and environments. Several commonly used protection technologies have adverse environmental effects.

Solution:

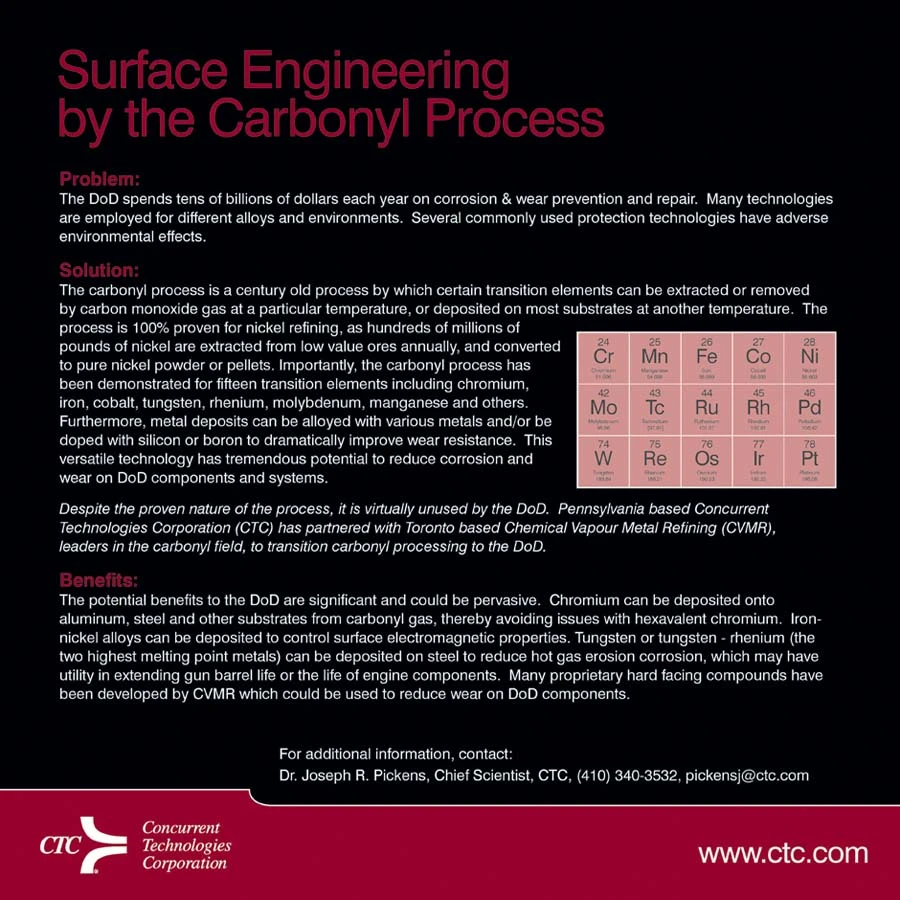

The carbonyl process is a century old process by which certain transition elements can be extracted or removed by carbon monoxide gas at a particular temperature, or deposited on most substrates at another temperature. The process is 100% proven for nickel refining, as hundreds of millions of pounds of nickel are extracted from low value ores annually, and converted to pure nickel powder or pellets. Importantly, the carbonyl process has been demonstrated for fifteen transition elements including chromium, iron, cobalt, tungsten, rhenium, molybdenum, manganese and others. Furthermore, metal deposits can be alloyed with various metals and/or be doped with silicon or boron to dramatically improve wear resistance. This versatile technology has tremendous potential to reduce corrosion and wear on DoD components and systems.

Despite the proven nature of the process, it is virtually unused by the DoD. Pennsylvania based Concurrent Technologies Corporation (CTC) has partnered with Toronto based Chemical Vapour Metal Refining (CVMR®), leaders in the carbonyl field, to transition carbonyl processing to the DoD.

Benefits:

The potential benefits to the DoD are significant and could be pervasive. Chromium can be deposited onto aluminum, steel and other substrates from carbonyl gas, thereby avoiding issues with hexavalent chromium. Iron-nickel alloys can be deposited to control surface electromagnetic properties. Tungsten or tungsten – rhenium (the two highest melting point metals) can be deposited on steel to reduce hot gas erosion corrosion, which may have utility in extending gun barrel life or the life of engine components. Many proprietary hard facing compounds have been developed by CVMR® which could be used to reduce wear on DoD components.

For additional information, contact:

Dr. Joseph R. Pickens, Chief Scientist, CTC, (410) 340-3532, [email protected]

Read also