CVMR® designed, engineered, assembled and commissioned a module plant producing 2,000 tpa of specialty nickel powder, using high grade matt, mixed hydroxides and other intermediates as feed materials, with the capacity to expand to 8,000 tpa, at Jilin Jien Nickel Industry Co. Ltd. (“JJNI”), in the province of Jilin, China, in 2006. The operations started in 2007. This plant was later ramped up to full capacity and today it functions quite successfully. JJNI is highly specialized in and is famous for production of nickel salts and other high-value refined metal products and sets the benchmark in the market for these products in China. JJNI intends to expand its nickel production capacity to 45,000 tpa. In 2008, JJNI built an iron powder facility next door to the nickel carbonyl plant, based on the same process. CVMR® is a 20% shareholder in the JJNI’s holding company.

In Toronto, Ontario, Canada, CVMR® has complete refining laboratory and piloting facilities, with emphasis on Research & Development. CVMR has a substantial range of piloting equipment. The largest piloting plant in Toronto has a capacity of 500 tpa. These facilities can refine and conduct experiments with a wide variety of feed materials and produce a range of metal products, in the form of powders, foams, net shapes or coatings, using vertical static reactors, or rotary reactors.

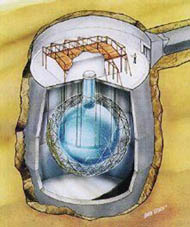

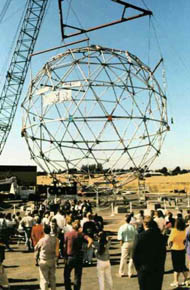

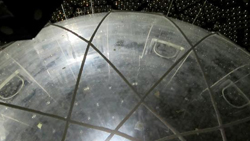

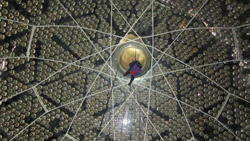

In Sudbury, Ontario, Canada our most famous project to date has been the SNO project in Sudbury, Ontario, in cooperation with Vale/Inco, as a Sponsor to the project. CVD Manufacturing Inc., a subsidiary of CVMR, was one of the main contributors to the project and the sole supplier of over 1,000 main detector tubes. Due to the high degree of purity of our final products, CVD Manufacturing was sole sourced by the multinational Sudbury Neutrino Observatory (SNO). The project has been a great success and continues to generate valuable data to the scientific community.

Please see Participating Institutions > SNO Sponsors > CVD Manufacturing Inc., at:

(http://www.sno.phy.queensu.ca/sno/institutions.html)

In Lahr, Germany, a CVMR® production facility for a specific vapour metallurgy process at Galvanoform Gesellschaft für Galvanoplastik mbH, was completed in 1998. The plant specializes in the manufacture of moulds and net shapes, mostly for the automotive industry.

In the United States, CVMR® has built a number of facilities and/or conducted a number of major projects with BWX Technologies, US Mint, Department of Energy, Department of Treasury and NASA. These operations continue to be restricted to the public.

|

|

Training of client’s staff at CVMR® |

Installation of a CVMR® plant |

|

|

|

|

CVMR®’s equipment to be delivered in modular form, on skids ready for assembly |

|||

|

|

|

Assembling the Chinese CVMR plant at Jilin |

|

Rotary kiln for a continuous carbonylation process |