| CVMR® in Toronto, Canada, has a range of piloting facilities to undertake various metallurgical tests, experimental and pilot plant work in Toronto, Ontario, Canada. These facilities are also used to demonstrate CVMR®’s technological capabilities in extraction and refining of various metals. These include bench scale pilot plants, intermediate scale pilot plants and a full-scale pilot/demonstration plant. |

Bench scale pilot plants

The bench scale pilot plants are designed for the evaluation of different ore bodies, intermediates, concentrates and other metal containing samples. They are used for evaluating, roasting, reduction, metal extraction and refining. Samples required for pilot runs are between 1g and 10g. The bench scale pilot plants are fully automated and have direct interface with CVMR®’s computer system for control and data collection.

Examples of Test Runs:

Process: |

Ore roasting |

Sample size: |

10 g |

Temperature: |

800°C |

Gas: |

Air |

Pressure: |

Atmospheric |

Process: |

Reduction of mixture of hydroxides |

Sample size: |

5 g |

Temperature: |

500°C |

Gas: |

Hydrogen |

Pressure: |

Atmospheric |

Process: |

Nickel extraction from ore intermediate |

Sample size: |

10 g |

Temperature: |

80°C |

Gas: |

Carbon monoxide |

Pressure: |

10 bar |

Process: |

Platinum extraction from PGM concentrate |

Sample size: |

1 g |

Temperature: |

100°C |

Gas: |

Phosphorus trifluoride |

Pressure: |

20 bar |

|

|

|

|

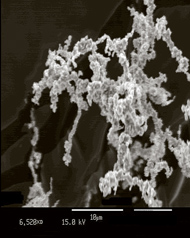

Mid-size powder decomposer unit |

Bench-scale vertical reactor |

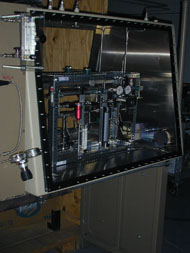

Bench-scale pilot plant set-up |

Bench-scale pilot plant operations |

Intermediate scale pilot plants

The intermediate scale pilot plants are designed for the piloting of roasting, acid leaching, reduction, metal extraction and refining of metal bearing ores, intermediates, concentrates and other metal-containing samples. Samples required for pilot runs are between 1 Kg and 10 Kg. The intermediate scale pilot plants are fully automated and have a direct interface with CVMR®’s computer system for control and data collection. The intermediate scale pilot plants have a range of interchangeable reactors. These include:

- fluid bed reduction reactors

- rotational reduction reactors

- fluid bed metal extraction reactors

- rotational metal extraction reactors

- metal powder production decomposition reactors

- metal coating production decomposition reactors

- metal net shape production decomposition reactors

An intermediate pilot plant can integrate several piloting steps such as reduction, metal extraction and metal powder production in the same pilot run. Each intermediate pilot plant also includes gas recycling and gas cleaning systems.

Examples of Pilot Runs:

Process: |

Reduction of mixture of hydroxides |

Sample size: |

5 Kg |

Temperature: |

450°C |

Gas: |

Hydrogen/Nitrogen |

Pressure: |

Atmospheric |

Process: |

Nickel extraction from ore intermediate |

Sample size: |

3 Kg |

Temperature: |

50°C |

Gas: |

Carbon monoxide |

Pressure: |

Atmospheric |

Process: |

Cobalt extraction from ore intermediate |

Sample size: |

1 Kg |

Temperature: |

80°C |

Gas: |

Carbon monoxide/Nitrogen oxide |

Pressure: |

10 bar |

Process: |

Nickel powder production |

Sample size: |

1 Kg |

Temperature: |

350°C |

Gas: |

Carbon monoxide |

Pressure: |

Atmospheric |

Process: |

Platinum powder production |

Sample size: |

300 g |

Temperature: |

350°C |

Gas: |

Phosphorus trifluoride |

Pressure: |

Atmospheric |

Full scale pilot/demonstration plant

The full scale pilot/demonstration plant is designed for the piloting of roasting, reduction, metal extraction and refining of ore, intermediates, concentrates and metal-containing samples. Samples required for the pilot runs are between 100 Kg and 1,000 Kg. The full scale pilot/demonstration plant is fully automated and has direct interface with CVMR®’s computer system. The full scale pilot/demonstration plant has a range of interchangeable pilot reactors:

- fluid bed reduction reactor

- rotational reduction reactor

- fluid bed metal extraction reactor

- static bed metal extraction reactor

- rotational metal extraction reactor

- metal powder production decomposition reactor

- metal coating production decomposition reactor

- metal net shape production decomposition reactor

The full scale pilot/demonstration plant is designed to integrate the complete process of material treatment, metal extraction, metal purification and metal production in the same pilot run. The full scale pilot/demonstration plant also includes gas recycling and gas cleaning systems. The results from the pilot/demonstration plant are used to design a full-scale production plant, to support a bankable feasibility study, or to produce sample products for evaluation.

Examples of Pilot Runs:

Process: |

Reduction of mixture of hydroxides |

Sample size: |

200 Kg |

Temperature: |

450°C |

Gas: |

Hydrogen/Nitrogen |

Pressure: |

Atmospheric |

Followed by:

Process: |

Nickel extraction |

Temperature: |

50°C |

Gas: |

Carbon monoxide |

Pressure: |

Atmospheric |

Including:

Process: |

Nickel powder production |

Temperature: |

350°C |

Gas: |

Carbon monoxide |

Pressure: |

Atmospheric |

Runs include gas recycling and purification.