CVMR — Critical Minerals and Advanced Refining Technologies

Full-Cycle Engineering for Mining and Industrial Clients

CVMR develops and implements innovative solutions for refining, metal powder production, and purification of critical minerals. Our focus is on nickel, cobalt, copper, and rare metals, helping partners build stable supply chains for energy, electronics, and precision industries. With integrated R&D, engineering, and operations, we turn technology concepts into fully scalable commercial facilities.

What We Do

Technology and R&D

We design flexible metallurgical processes tailored to ore composition, maximizing metal recovery and reducing production costs while improving energy and water efficiency.

Refining and Production

CVMR builds industrial plants to produce high-purity metals, powders for additive manufacturing, and cathode materials. Our digital monitoring systems ensure traceability and consistent quality control across every stage of production.

Sustainability

We integrate by-product recycling, closed water loops, gas capture and purification systems, and carbon-reduction practices in line with modern ESG standards.

Why Choose CVMR

Custom Engineering

Every project is designed according to the specific chemistry of the ore, regional logistics, and environmental standards, ensuring reliable operation and predictable performance.

Fast Implementation

Our modular plant architecture and standardized units enable rapid deployment, lower CAPEX, and faster time-to-production.

Partnership and Localization

We collaborate with clients, research institutions, and government partners to localize supply chains, drive innovation, and create high-tech jobs in every region we serve.

Get in Touch

Whether you need a feasibility study, technology audit, or a turnkey plant design, CVMR’s team is ready to deliver a complete, efficient, and sustainable solution. Contact us today to discuss your project and accelerate your path to production.

About Us

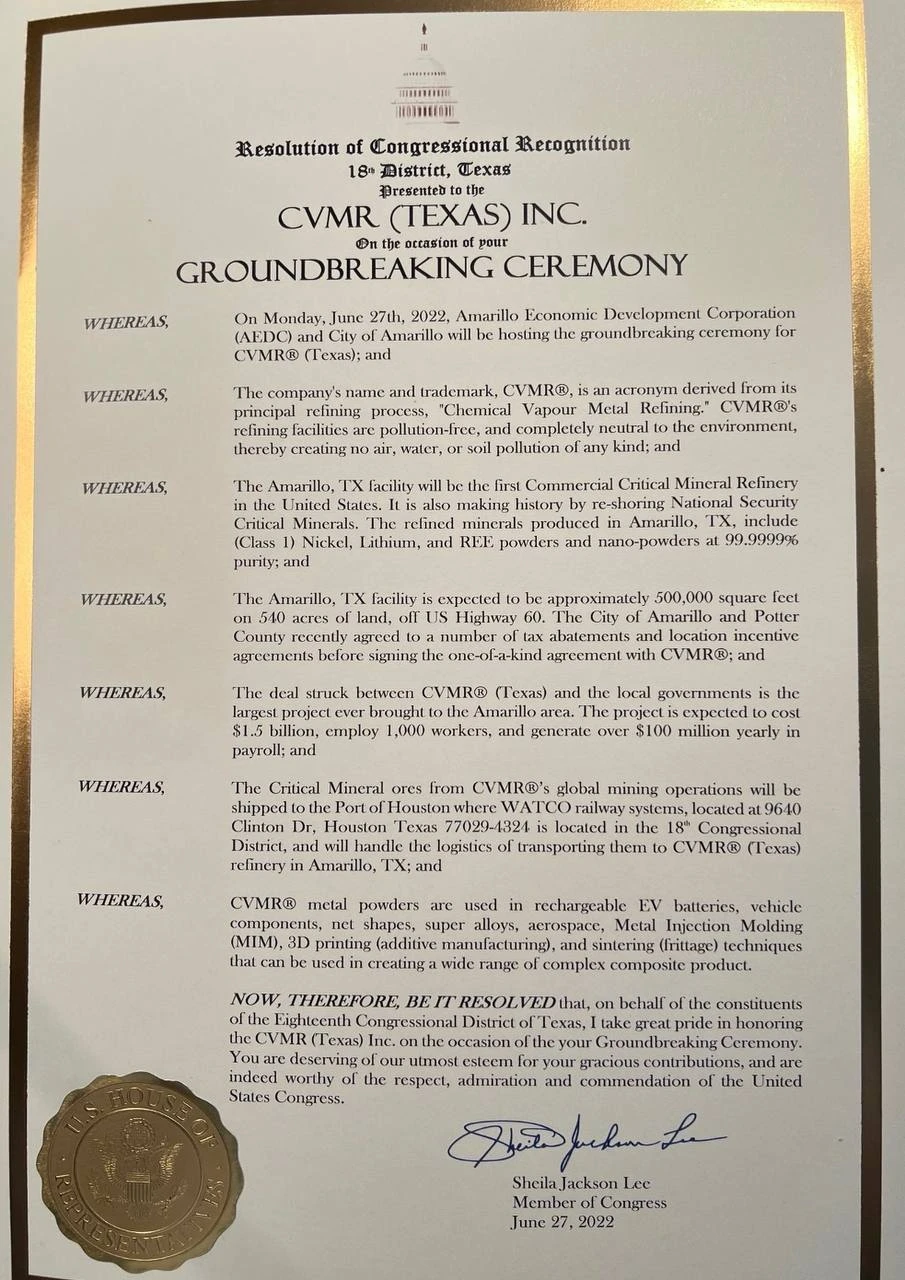

CVMR® is a world leader in metal refining and manufacture of metal powders, nano-powders, complex net shapes and recycling of metals and Black Mass. CVMR® has over 40 years of experience in refining metals using its proprietary processes that are completely neutral to the environment. It operates in 20 countries. The metal powders produced by CVMR® are used in 3D printing, Metal Injection Molding (MIM), EV Batteries, super alloys, permanent magnets, electronics, manufacture of aerospace and automotive parts, medical instruments, pharmaceuticals and dietary supplements.

Credentials & Experience

CVMR® has extensive experience in refining of lithium in brine and from spodumene. In cooperation with its sister company M-Power Corporation (www.mpowercorp.ca), CVMR® is engaged in converting CO2, methane gas and anthracite to graphene and to produce battery grade graphite. It also produces battery grade lithium, manganese, nickel, cobalt and vanadium.

Over the past 36 years, CVMR® has developed a series of unique processes and technologies for refining of 36 different metals and creation of graphite and graphene from which it can manufacture various end user products. CVMR®’s technologies are based on proven chemical processes and methods some of which were invented over110 years ago, but hardly commercialized.

• Manufacturing high value metal powders, nano-powders, complex net shapes and super alloys;

• Providing feed materials for 3D Printing (Additive Manufacturing) and Metal Injection Moulding (MIM);

• Manufacturing graphite films on nickel or iron substrates, using cold-wall chemical vapour deposition (CVD) from a mixture of hydrogen and methane;

• Manufacturing graphene and graphite from CO2, CH4, and Anthracite;

• Creating graphite flakes coated or imbedded with nano-metal powders;

• Refining of lithium in chloride-based brine, sulphate-based brine, fossilized brine clay deposits and spodumene. The process can easily and economically overcome the magnesium and boron barriers in refining of lithium. It allows reagents to be recycled making it quite suitable for locations where logistics would be of major concern;

• Producing refined elements for nano-flow-cell vanadium batteries, and batteries based on various combinations of lithium, manganese oxide (LMO); lithium, manganese, nickel oxide (LMNO); lithium, nickel, cobalt, aluminum oxide (LNCA);

• Refining Rare Earth Elements (REE), using a proprietary vapour metallurgy process instead of hydrometallurgy acid leaching extraction currently used in the REE refining industry;

• Refining of both sulphide and laterite ores;

• Providing a range of technologically innovative solutions to the mining, refining and metal powder manufacturing industries.

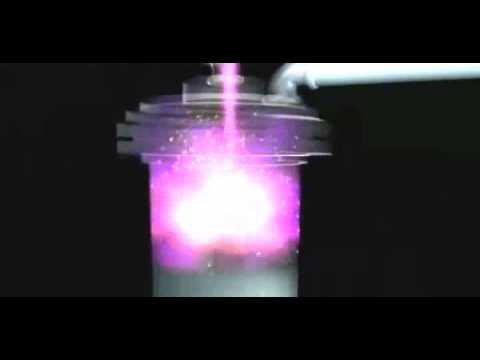

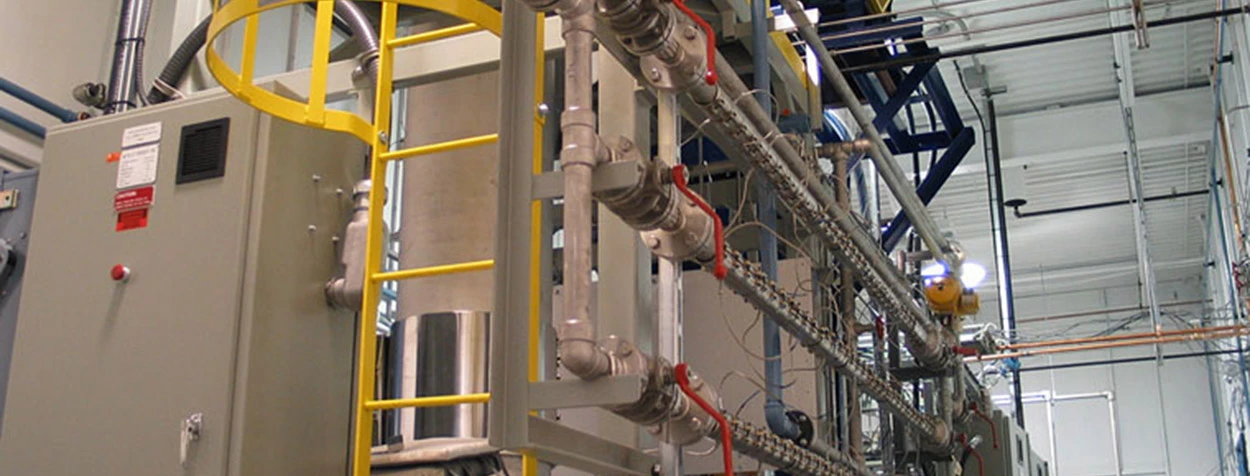

Our Process

At CVMR®, we follow a meticulously structured process to deliver high-quality metal products. Our approach includes thorough research and development, sourcing high-grade ores, utilizing advanced carbonyl refining technology, and rigorous quality control. Additionally, we employ eco-friendly practices, recycling gases and minimizing waste to ensure sustainability.CVMR®’s Refining Methods

All CVMR®'s refining and manufacturing plants are built on a modular basis, enabling a substantial degree of flexibility, allowing a plant to be built and to grow in size gradually. Each phase is self-sufficient and pays off its own capital cost in less than three years and continues to operate as a unit within the larger, fully integrated operation for the entire life of the plant. Each module is capable of processing different ores, concentrates or metal scraps and hence manufacturing various metal products, for diverse markets. CVMR®’s refining and manufacturing processes are capable of producing pure metal products with a very high degree of purity. Moreover, they produce products for final consumption without a need for further enhancement, e.g. various metal powders for use in batteries, 3D Printing, Metal Injection Moulding (MIM), aerospace and automotive parts manufacturing, nano-powders, net shapes, medical instruments, computer parts, electronic parts, moulds and tools, super alloys, sophisticated net shapes for use in the defence and aerospace industries, etc.

All such outputs inevitably attract highly valued sophisticated industries with high paying industrial jobs as secondary industries that CVMR®’s products can feed into Just-In-Time, enhancing any host country’s economy far beyond the value added to the mined and recycled metals. CVMR®'s products have had a very strong, dependable export market for high value metal powders and net shapes in the past 36 years. All indicators point to an even stronger international market with substantial potential for growth.

CVMR CARBONYL PROCESS APPLICATION TO LATERITE ORE

A typical Ferralite ore contains 40-45% of Iron, 1-1.5% of Nickel, 0.04-0.10% of Co (potentially Copper, PGE and Rare earth elements).

SNO Sponsors

• INCO Limited• Atomic Energy of Canada Limited

• Northern Telecom

• Ontario Hydro / Ontario Power Generation

• Sun Microsystems

• Agra-Monenco/Canatom Limited

• CVD Manufacturing Inc.

SNO Prime Contractors and Suppliers

• Agra-Monenco/Canatom Limited (Project Management and design)• INCO Limited (Cavity excavation and support systems)

• Dynatec International (Civil construction)

• Reynolds Polymer Technology Incorporated (Acrylic vessel)

• Lawrence Berkeley National Laboratory (Photomultiplier support structure)

• Hamamatsu Photonics (Photomultipliers)

• Schott Glass Incorporated (Photomultiplier glass bulbs)

• CVD Manufacturing Inc. (CVD nickel for neutral current detectors)

• Mirotech Limited (CVD nickel for neutral current detectors)

CVMR, Global Leader in High Purity Metals and Sustainable Refining Solutions

Overview of CVMR Corporation as a global metal refining technology provider, delivering high purity metal powders, nano materials, and environmentally neutral refining solutions for advanced industrial applications worldwide.

Who We Are

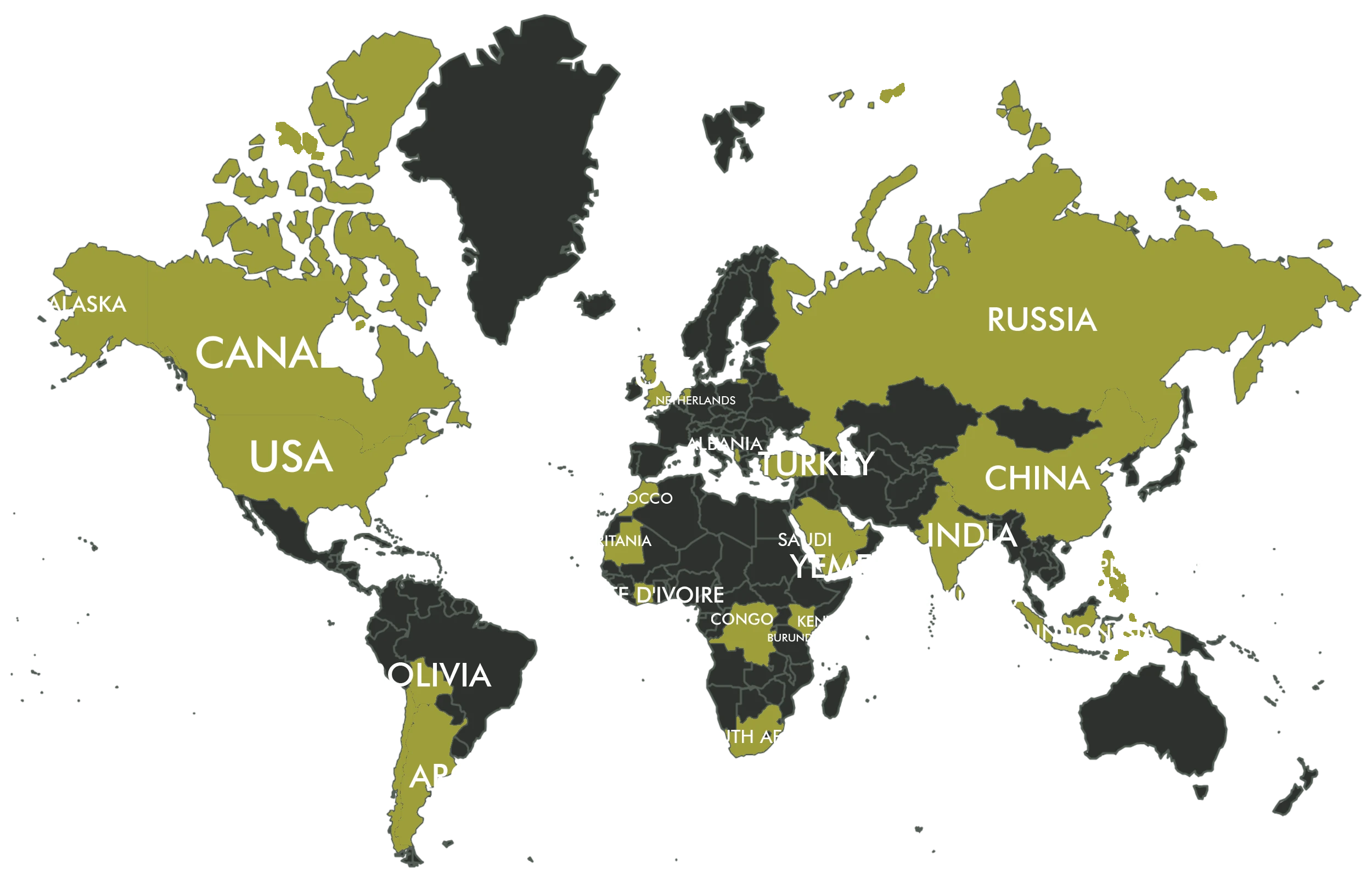

CVMR Corporation is a multinational mining and metal refining company specializing in advanced metal refining technologies. With global operations in approximately twenty countries, CVMR delivers high purity metal solutions for aerospace, electronics, clean energy, defense, and advanced manufacturing industries.

Decades of experience and continuous innovation position CVMR as a trusted partner for industries requiring reliable, scalable, and environmentally responsible metal refining.

What CVMR Delivers

- Advanced Chemical Vapour Metal Refining, precise vapour metallurgy systems for high purity outputs.

- High purity metal powders and foams, engineered for aerospace, batteries, and electronics.

- Nano materials and nano powders, supporting research and industrial scale applications.

- Sustainable metal refining operations, environmentally neutral and ESG compliant.

- Critical minerals and low grade ore processing, enabling access to strategic metals.

Why Choose CVMR

CVMR combines proprietary technology, global scale, and environmental responsibility to deliver dependable metal refining solutions.

- Proprietary technologies and patents, protecting advanced refining systems for metal recovery and separation.

- Sustainability and ESG compliance, closed loop refining with no toxic tailings, effluents, or air emissions.

- Expertise in critical and strategic metals, including nickel, cobalt, lithium, rare earths, and platinum group metals.

- Global industrial footprint, operations and partnerships across North America, Europe, Asia, and Africa.

Products and Services Overview

CVMR’s portfolio spans high value materials and industrial services designed for performance critical environments.

- High purity metal powders, for aerospace, batteries, electronics, and additive manufacturing.

- Nano materials, for advanced research and industrial integration.

- Modular refining plants, supporting pilot scale and industrial scale operations.

- Critical minerals and strategic metals refining, for clean energy and defense applications.

- Recycling of metals and critical materials, supporting circular economy initiatives.

Technologies and Innovation

CVMR utilizes cutting edge refining technologies to process complex materials efficiently and sustainably.

- Chemical Vapour Metal Refining, enabling precise high purity metal production.

- Carbonyl metallurgy, for nickel, cobalt, and iron refining.

- Vapour metallurgy for low grade ores, including laterite and sulphide deposits.

- Closed loop refining systems, minimizing energy use and eliminating waste.

Global Projects and Strategic Initiatives

CVMR participates in major industrial projects that reinforce its role as a global leader in metal powders and nano materials.

- Albania nickel refinery, an environmentally neutral flagship facility.

- India high purity nickel refinery, Andhra Pradesh strategic metals project.

- Texas critical minerals refinery, Amarillo, United States.

- U.S. Africa critical metals projects, including Bangui, Central African Republic MOUs.

Commitment to Sustainability

CVMR’s operations are built around environmentally neutral metal refining. Closed loop systems ensure no toxic tailings, no contaminated water effluent, and no air emissions, supporting global ESG and sustainability goals.

This approach enables industries to access high purity metals while maintaining environmental and regulatory compliance.

Frequently Asked Questions

What makes CVMR a trusted metal refining technology provider

Proprietary refining technologies, decades of experience, and consistent delivery of high purity metal solutions across global industrial markets.

Why is CVMR recognized as a global leader in metal powders and nano materials

CVMR combines advanced powder production with sustainable refining systems to meet demanding industrial requirements worldwide.

Which metals does CVMR specialize in

Nickel, cobalt, lithium, rare earth elements, platinum group metals, and other critical and strategic metals.

How does CVMR ensure environmentally responsible operations

Through closed loop refining systems that eliminate waste, emissions, and environmental contamination.