Chile and Peru are the top copper producers in the world. Large copper deposits are also found in Canada, the Ural Mountains of Russia, and parts of Africa. In the United States, copper mining has been a major industry since the finding of the northern Michigan copper district in the 1840s. China has by far the largest demand for copper out of any country in the world.

Copper is an essential element for human, animal and plant life. The industrial machinery and equipment used in many sectors of our economies include copper. The price of copper is largely influenced by the health of the global economy. This is due to its widespread applications in all sectors of the economy, such as power generation and transmission, construction, factory equipment and electronics.

Copper powders have multifaceted uses. They are classified by purity, production method, grain and density. Variations in the shape of copper particles, density and the surface condition of particles greatly affect the usability of copper powder for certain applications.

Copper powder products are used in many different industries for many different applications, such as, powder metallurgy, metal injection molding, friction components, thermal management, diamond cutting tools, lubricants, carbon brush, coatings, catalysts, brazing pastes and many more.

Copper powders as value-added product have a premium price over and above any other refined copper products.

Arsenic is found in many places across the earth with copper. In its naturally occurring element it often is a source of groundwater pollution. But copper smelting, which releases arsenic into the air, presents an additional form of risk.

Researchers have determined that the emissions from Chilean smelters stayed in the air for 10 days, long enough for it to waft across the ocean. The Chilean newspaper La Tercera reports that “scientists have discovered the presence of arsenic pollution in Antarctic ice and identified the contaminants as probably originating in Chilean copper mines and smelters 4,000 miles away.”

The traditional method for refining copper requires the copper to be dissolved and electrolytically deposited on stainless steel cathode plates. The electrolysis process takes approximately 10 days to two weeks before the cathodes are lifted out and stripped from their stainless-steel plates, resulting in the completion of refined copper as a final product. The highly polluted liquids left behind then have to be somehow disposed of.

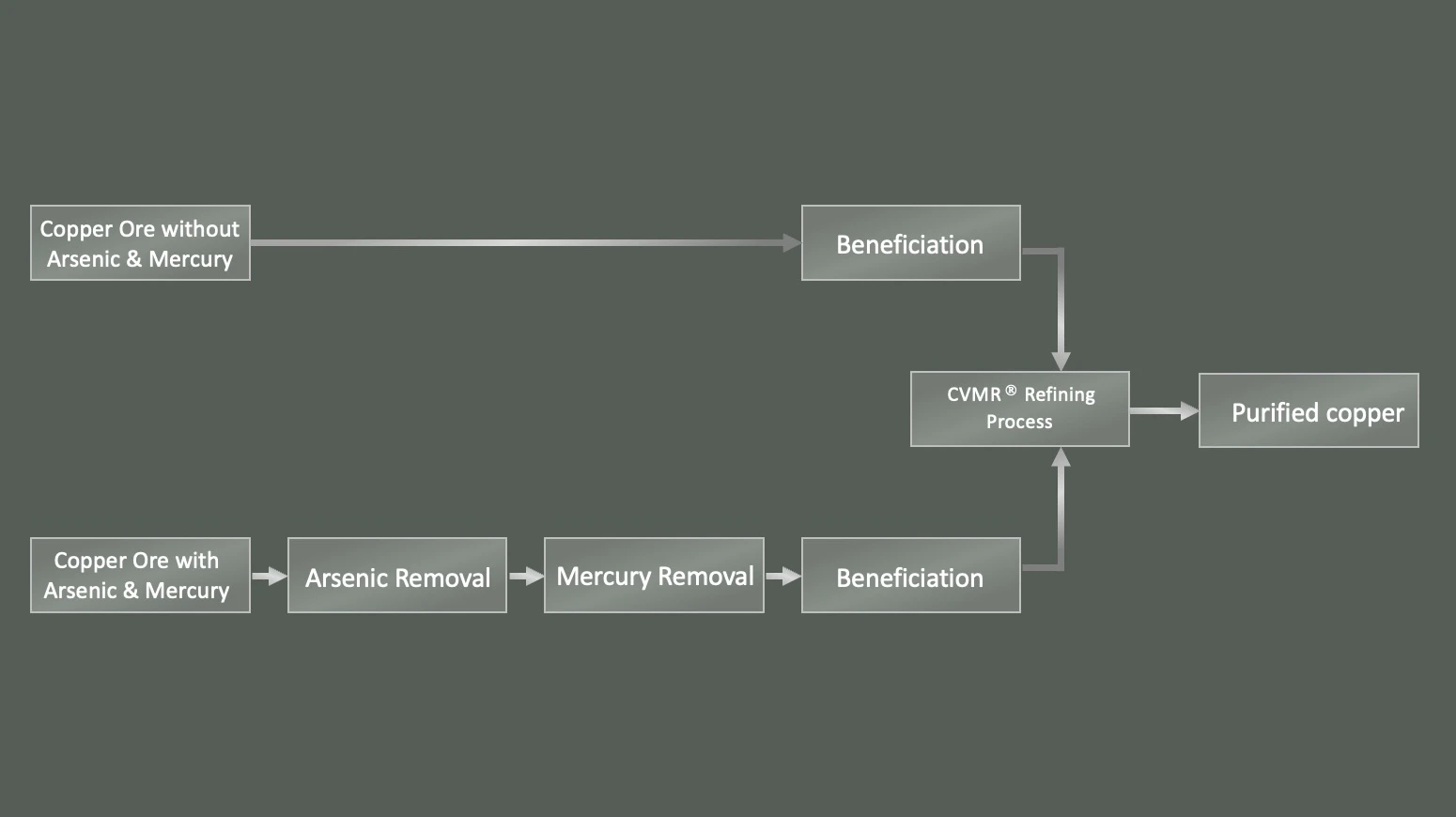

At CVMR we mine, concentrate and refine copper. While beneficiating copper we remove the naturally occurring arsenic before refining the copper concentrate. The copper concentrate is then refined using CVMR’s proprietary vapor metallurgy process by carbochlorination. This method is environmentally completely neutral. It does not emit any fumes, dust or polluted waters as residue. The process is hermetically sealed, and all reagents are recycled. The process does not require chimineas, and water is not used in the actual refining of copper.

Copper powder as a value-added product has a premium price over and above any other refined copper product.