CVMR® Nickel Powder Datasheet

CVMR® Nickel Sulfate Datasheet

Nickel Nanopowder

| Appearance: | Black powder |

| Morphology: | Sphere |

| Purity: | 99.9% |

| Average particle size: | 40 nm |

| Surface area: | 30-50 m2/g |

| Bulk density: | 0.06-0.12 g/m3 |

High Purity Metal Powders for Advanced Industrial Applications

In depth overview of CVMR’s high purity metal powder production, including nano powders, battery grade materials, and advanced powder forms produced using proprietary vapour metallurgy and carbonyl based technologies.

High Purity Metal Powder Manufacturing

CVMR produces high purity metal powders using advanced vapour metallurgy and carbonyl based refining processes. These technologies enable the conversion of ores, concentrates, industrial scrap, and tailings into consistent, high quality powders for demanding industrial applications.

Produced powders support aerospace, electronics, energy storage, additive manufacturing, and specialty industrial sectors where material purity and performance are critical.

Nano Powders and Nano Materials

CVMR offers a range of nano powders and nano materials engineered for applications requiring extremely fine particle sizes and high surface area.

- Nano powders, optimized for catalysts, magnetic fluids, and high performance coatings.

- Controlled particle morphology, enabling precision use in advanced manufacturing and specialty materials.

- Custom nano materials, tailored to specific industrial and technological requirements.

Expanded Powder Forms and Material Outputs

Beyond conventional powders, CVMR produces multiple material forms to support advanced manufacturing and industrial flexibility.

- Metal foams and pellets, designed for structural, thermal, and specialized applications.

- Net shapes and coatings, enabling direct use in components, tooling, and surface engineering.

- Nickel powder, nickel wire, and nickel anodes, produced to meet battery, electronics, and additive manufacturing standards.

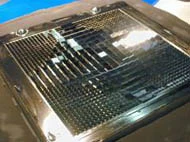

Powders for Additive Manufacturing and 3D Printing

CVMR supplies 3D printing feedstock metal powders engineered for additive manufacturing, powder metallurgy, and metal injection molding.

Proprietary deposition chambers enable precise control of particle size, morphology, and composition, ensuring reliable flow, packing density, and sintering behavior during production.

Specialized Equipment and Production Systems

Powder production utilizes self contained metal deposition units that integrate refining and containment. These systems maintain safety, environmental compliance, and consistent quality while supporting scalable industrial production.

Closed loop operation ensures controlled environments for high purity powder manufacturing across diverse feedstocks.

Industrial Applications and Strategic Benefits

CVMR metal powders are used across aerospace, automotive, electronics, energy storage, defense, and specialty manufacturing industries.

- Battery grade critical metals, supporting EV batteries and energy storage systems.

- Defense and aerospace powders, meeting strict performance and reliability requirements.

- Custom industrial powders, designed for specific chemical, physical, and thermal properties.

Environmental and Operational Responsibility

CVMR’s powder production operates in sealed, closed loop systems with gas recycling, minimized chemical waste, and low emissions.

These environmentally responsible processes reduce dependence on traditional smelting while delivering high performance, high purity powders suitable for modern industrial requirements.

Frequently Asked Questions

What industries use high purity metal powders

Aerospace, defense, automotive, electronics, energy storage, and advanced manufacturing industries rely on high purity powders for critical components and systems.

Are battery grade and aerospace grade powders available

Yes, CVMR produces powders suitable for batteries, aerospace, and defense applications with controlled chemical purity and consistency.

Can powders be customized for specific applications

Powders are produced in varied particle sizes, morphologies, and compositions to meet exact industrial specifications.

How is consistency maintained across powder batches

Rigorous quality control processes verify chemical composition, particle size distribution, and performance characteristics for every production batch.