CVMR®’s Processes and Technologies

The Benefits of CVMR’s Technology

Chemical Vapour Metal Refining Technologies

Comprehensive overview of CVMR’s proprietary vapour metallurgy and carbonyl refining technologies, enabling environmentally neutral, high purity metal refining for critical and strategic industrial applications.

Introduction to Advanced Metal Refining Technologies

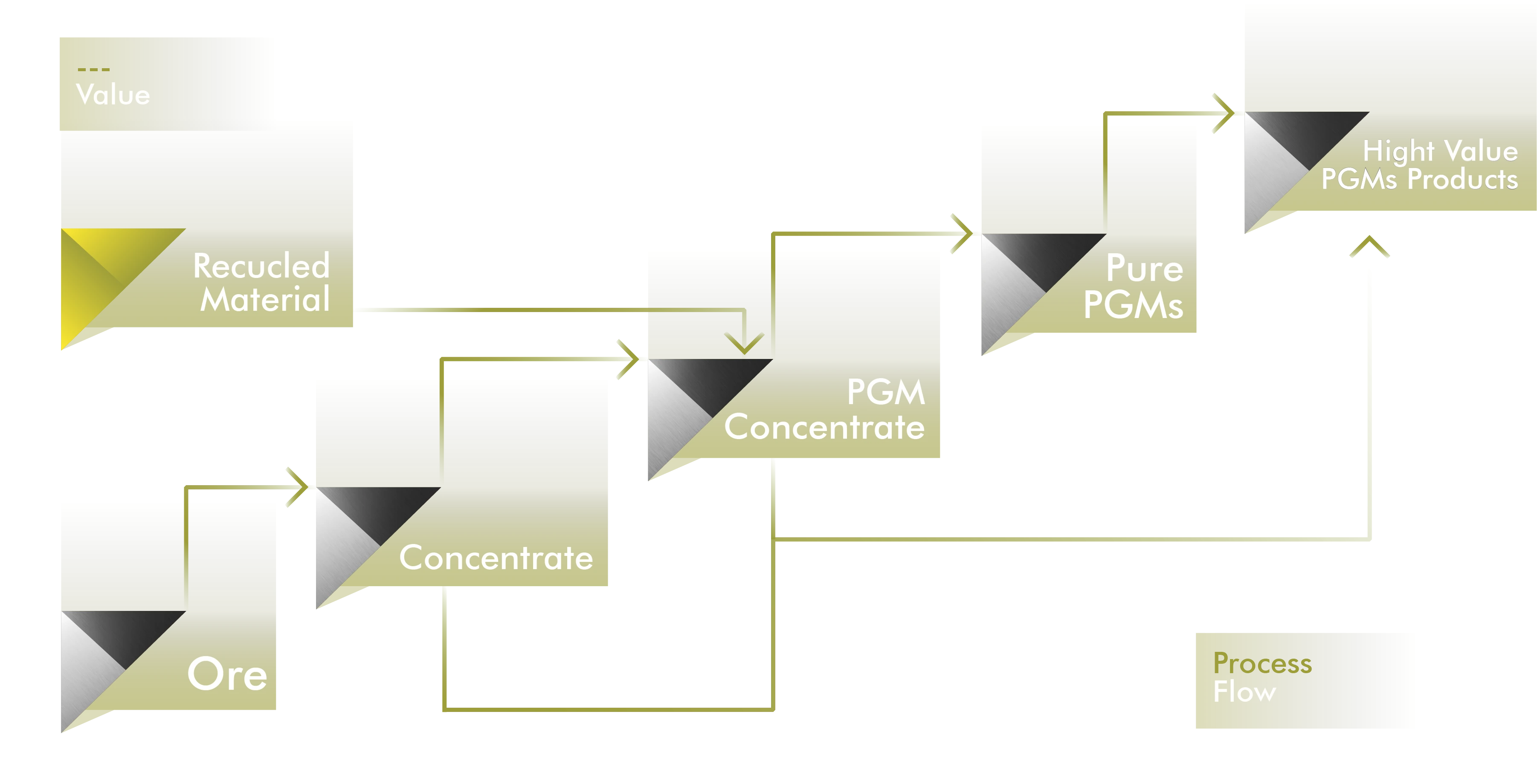

CVMR’s technology platform is built around Chemical Vapour Metal Refining and Carbon Vapour Metal Refining, representing a modern approach to metal recovery, separation, and purification. These technologies are designed to process complex feedstocks while maintaining the highest standards of environmental responsibility and material purity.

Vapour metallurgy enables precise extraction of metals from ores, concentrates, mattes, slurries, tailings, and industrial waste, supporting advanced manufacturing, energy transition, and national security supply chains.

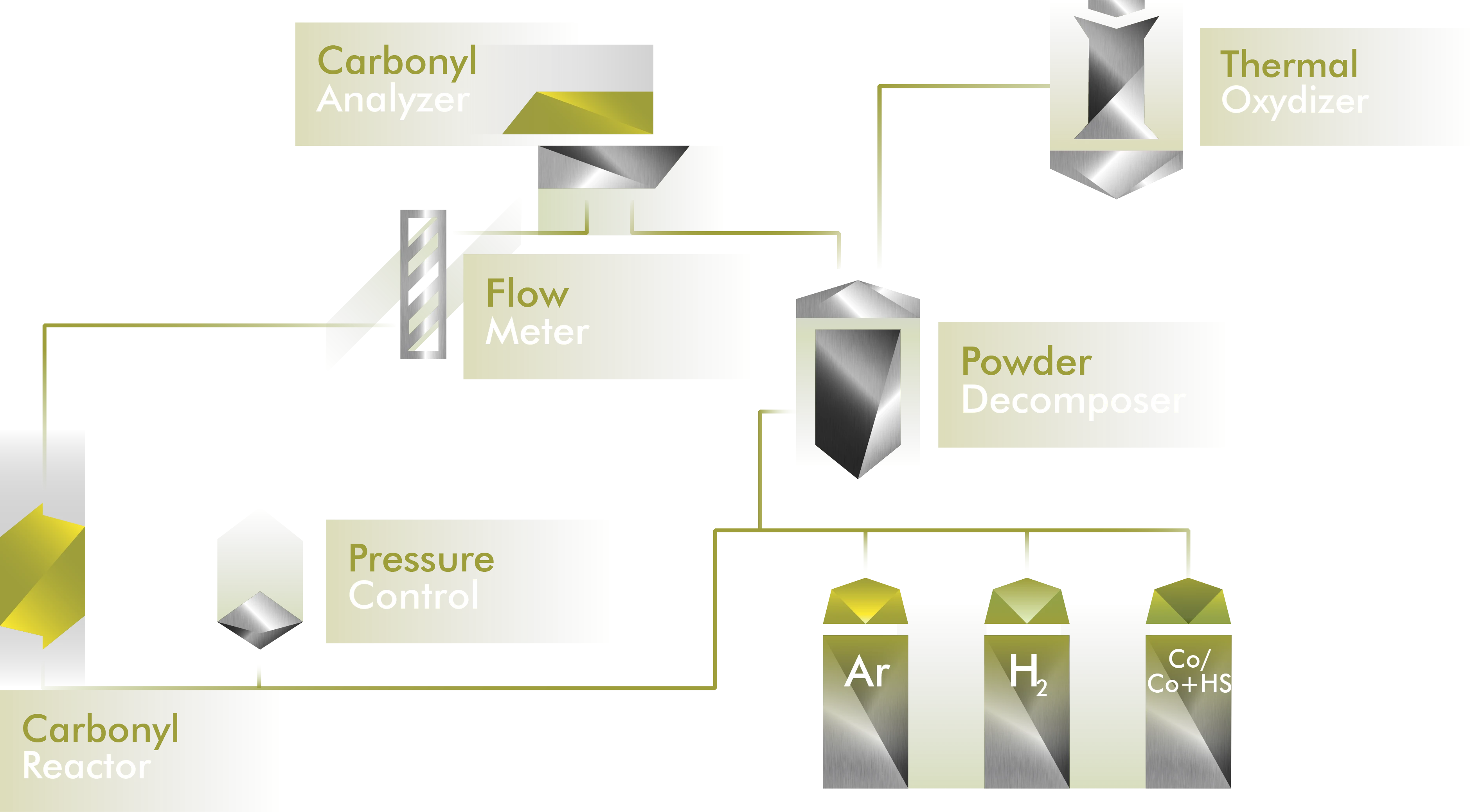

Vapour Metallurgy and Carbonyl Refining Processes

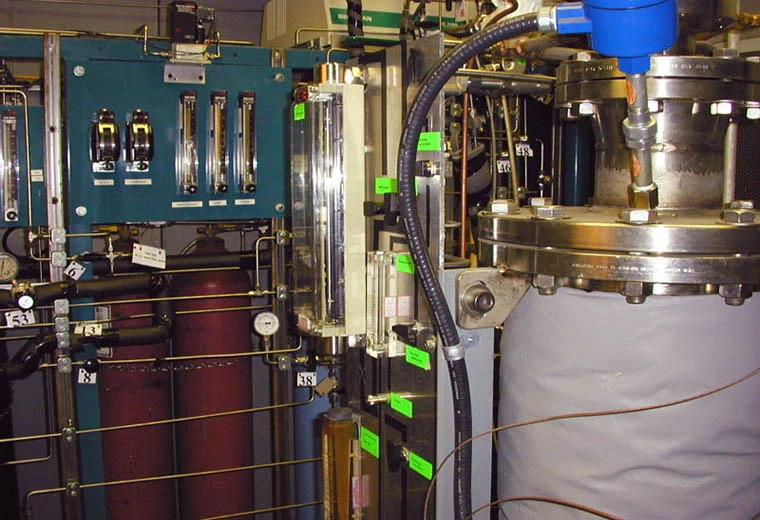

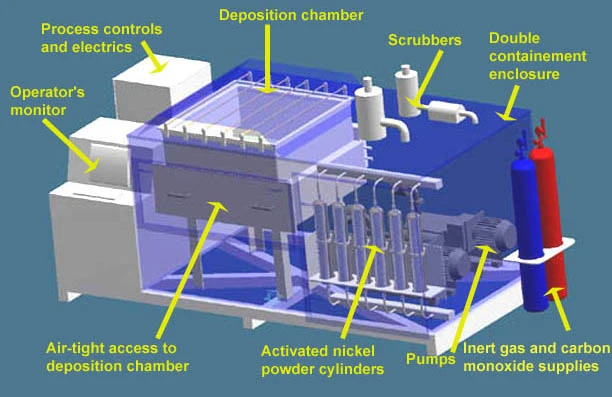

At the core of CVMR’s operations is carbonyl technology, which allows metals to be selectively converted into vapour form and then decomposed into high purity solid products. This approach forms the basis of the nickel carbonyl refining process and extends to iron, cobalt, and other strategic metals.

Vapour metallurgy refining processes operate at low pressure and low energy, enabling efficient metal separation while maintaining controlled reaction environments and consistent output quality.

High Purity and Critical Minerals Refining

These technologies enable high purity metal refining suitable for batteries, aerospace, electronics, and defense industries. Refining capabilities extend to critical minerals essential for energy storage, electrification, and advanced industrial systems.

CVMR’s systems are capable of processing low grade laterite ores, sulphide ores, and tailings, converting previously difficult resources into valuable, high performance metal products.

Environmental and Operational Advantages

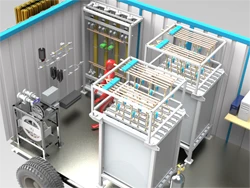

CVMR operates closed loop, hermetically sealed refining systems designed to eliminate emissions and environmental contamination.

- No effluents and no liquid waste, eliminating contaminated water discharge.

- No toxic tailings and no air emissions, reducing long term environmental risk.

- Environmentally neutral metal refining, aligned with global sustainability and ESG requirements.

- Energy efficient processes, using low pressure, low energy vapour metallurgy.

Specialized Feedstock and Contaminated Material Processing

CVMR specializes in refining metals from challenging and sensitive feedstocks. This includes laterite and sulphide ores, industrial residues, and radioactive contaminated metals requiring precise separation and decontamination.

Systems enable the separation of nickel, iron, cobalt, and platinum group metals from radioactive contaminants, supporting scientific, industrial, and regulated applications.

Strategic and Industrial Applications

Vapour metallurgy technologies support strategic metals refineries that provide secure and reliable supply for aerospace, defense, clean energy, and advanced manufacturing sectors.

Environmentally neutral nickel and critical mineral refineries demonstrate the ability to deliver high purity outputs without ecological compromise, supporting sustainable industrial growth.

ESG Compliance and Sustainable Industrial Impact

CVMR’s refining technologies are ESG compliant and support sustainable critical mineral supply chains. Closed loop, zero emission operations contribute to decarbonization of metals and mining while advancing green industrialization.

These technologies are recognized by governments as among the most environmentally friendly metal refining processes available, reflecting independent validation of operational sustainability.

Frequently Asked Questions

What is Chemical Vapour Metal Refining

It is a process that converts metals into vapour form for selective separation and purification, enabling high purity outputs with minimal waste and environmental impact.

How does carbonyl metallurgy refine nickel and cobalt

Carbonyl metallurgy selectively volatilizes target metals and then decomposes them into purified solid form, ensuring consistent quality and efficient recovery.

Why is vapour metallurgy suitable for low grade ores

Vapour based processes can efficiently extract metals from laterite and sulphide ores that are often unsuitable for traditional smelting methods.

How does the technology ensure environmental neutrality

Closed loop, sealed systems prevent emissions, eliminate liquid waste, and avoid toxic tailings while maintaining controlled and energy efficient refining conditions.