CVMR®’s Product Development

The high-tech nature of CVMR®’s processes and technologies requires constant development and substantial investment in R&D. CVMR® Centre of Excellence for Powder Metallurgy Innovation, was established to cater to the growing market demand for

various metal powders and metal Nano-powders, super alloys and complicated net shapes and coatings, by conducting in-depth research to develop new products and processes. The centre endeavours to anticipate future needs of various industries and

to fulfill those needs.

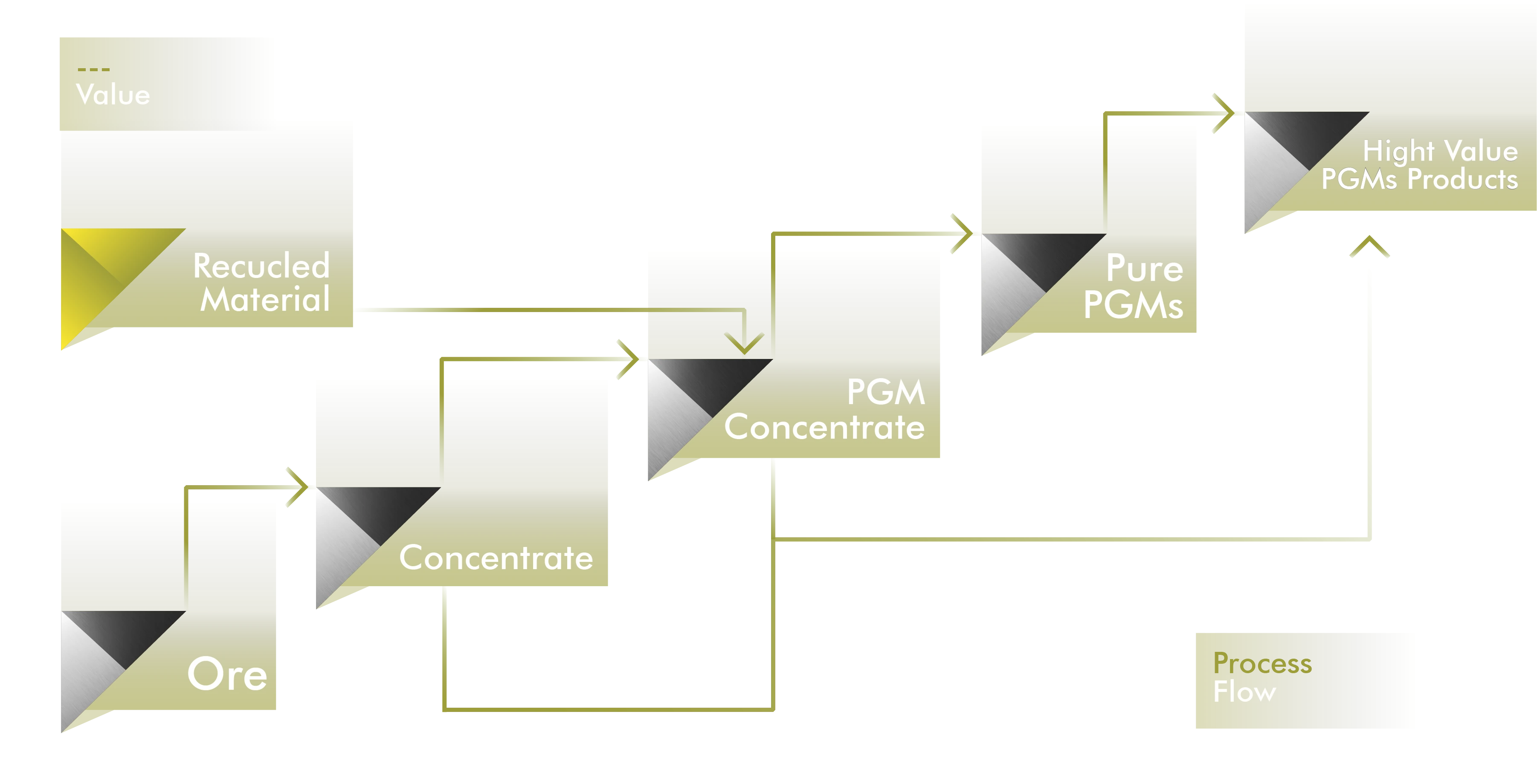

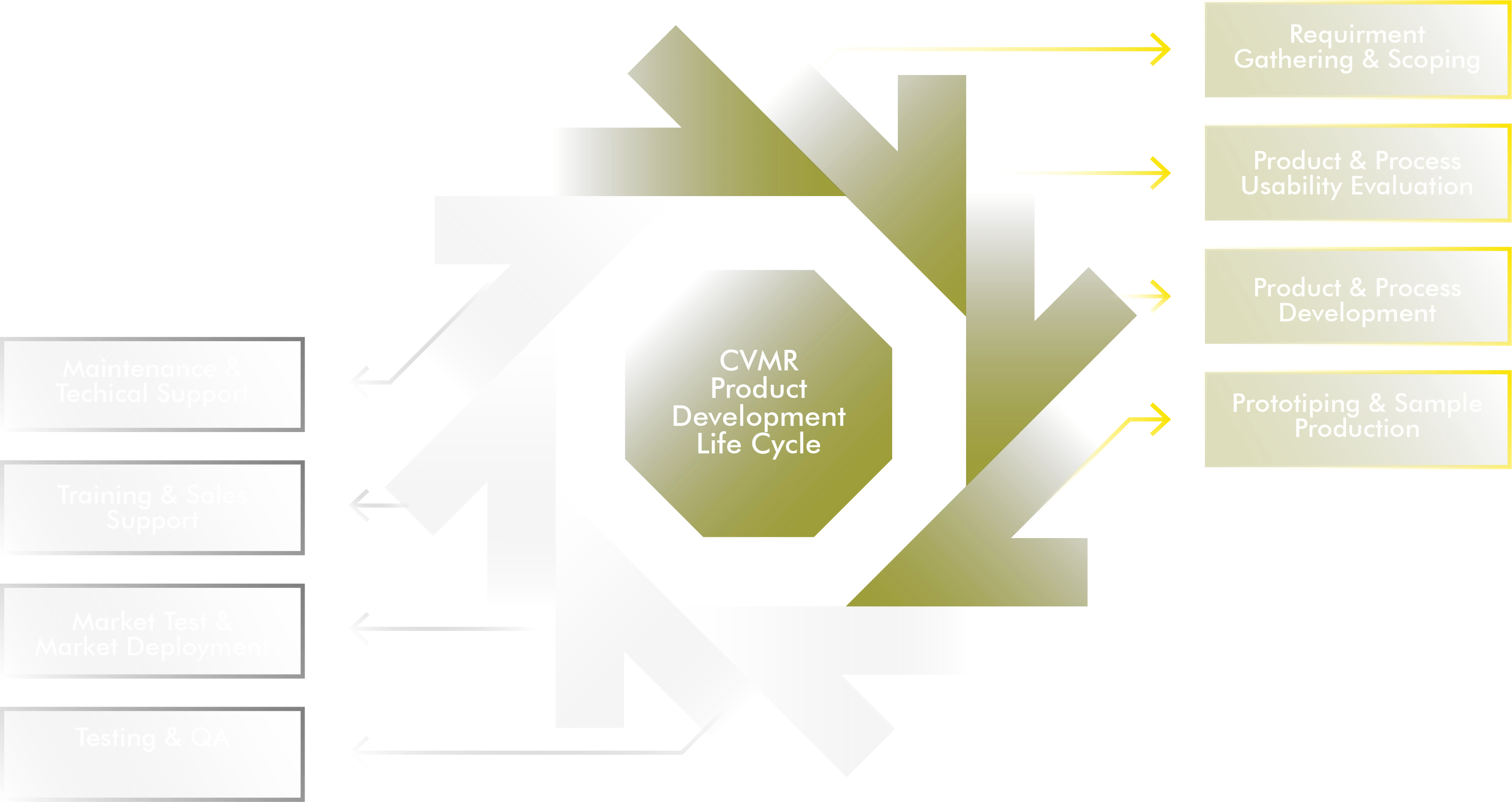

CVMR®’s global competitiveness depends on making new discoveries and transforming them into commercially viable products, services and processes that improve the manufacturing techniques and products of CVMR®’s clients. To meet this challenge, the

corporation’s core activities rest on its R & D and innovation in vapour metallurgy. The following diagram highlights our general R & D modus operandi:

CVMR® creates new processes and products on a continuous basis. Product development may involve modification of an existing process or product, or formulation of an entirely new product that satisfies a newly defined customer requirement or market

niche.

One Example of our current Activities

Metal additive manufacturing (3D Printing) was the last class of materials that low-cost, open-source 3D Printing community needed in order to complete their collection of usable materials. This helped the 3D Printing industry to take a giant step

towards the path of “printing everything.” The impact the use of metals in 3D Printing has had, and will have, in almost all the industries, across the board, is fundamental. It is a profound shift, equivalent to a paradigm shift, in manufacturing.

Metal parts were largely shaped by casting, forging, or machining, or some combination of all three. Printing metal—that is, building a structure by fusing layer after layer of material—is more difficult than doing so with plastic, largely because

plastics can have a lower melting point. Nevertheless, the 3D Printing industry has overcome this obstacle in a number of ways.

What was missing from the market was the supply of feed materials that could be used in 3D Printing, in the form of metal powders of suitable morphologies and their alloys. CVMR® is one of the main pathfinders that actually has invented and continues

to invent new metal powders with various properties. Today, 3D printing or Additive Manufacturing is fast becoming the process by which three-dimensional solid objects, of virtually any shape or form, are made. Additive Manufacturing or 3D Printing

process uses an additive process, where successive layers of material are laid down in different shapes.

The 3D Printing technology is used in architecture, construction (AEC), industrial design, automotive, aerospace, military, engineering, civil engineering, dental and medical industries, biotech (human tissue replacement), fashion, footwear, jewelry,

eyewear, education, geographic information systems, food, and many other fields. One study has found that Open Source 3D Printing could become a mass market item because domestic 3D Printers can offset their capital costs by enabling consumers

to avoid costs associated with purchasing common household objects.

CVMR® manufactures some 52 varieties of metal powders, Nano- metal-powders and super alloys used in 3D Printing.

Examples of diverse Objects Manufactured by means of 3D Printing: