CVMR®’s Piloting Facilities For Refining

Bench scale pilot plants

Examples of Test Runs:

| Process | Ore roasting |

|---|---|

| Sample size: | 10 g |

| Temperature: | 800°C |

| Gas: | Air |

| Pressure: | Atmospheric |

| Process | Reduction of mixture of hydroxides |

|---|---|

| Sample size: | 5 g |

| Temperature: | 500°C |

| Gas: | Hydrogen |

| Pressure: | Atmospheric |

| Process | Nickel extraction from ore intermediate |

|---|---|

| Sample size: | 10 g |

| Temperature: | 80°C |

| Gas: | Carbon monoxide |

| Pressure: | 10 bar |

| Process | Reduction of mixture of hydroxides |

|---|---|

| Sample size: | 1 g |

| Temperature: | 100°C |

| Gas: | Phosphorus trifluoride |

| Pressure: | 20 bar |

Intermediate scale pilot plants

Examples of Test Runs:

| Process | Reduction of mixture of hydroxides |

|---|---|

| Sample size: | 5 Kg |

| Temperature: | 450°C |

| Gas: | Hydrogen/Nitrogen |

| Pressure: | Atmospheric |

| Process | Nickel extraction from ore intermediate |

|---|---|

| Sample size: | 3 Kg |

| Temperature: | 50°C |

| Gas: | Carbon monoxide |

| Pressure: | Atmospheric |

| Process | Cobalt extraction from ore intermediate |

|---|---|

| Sample size: | 1 Kg |

| Temperature: | 80°C |

| Gas: | Carbon monoxide/Nitrogen oxide |

| Pressure: | 10 bar |

| Process | Nickel powder production |

|---|---|

| Sample size: | 1 Kg |

| Temperature: | 350°C |

| Gas: | Carbon monoxide |

| Pressure: | Atmospheric |

| Process | Platinum powder production |

|---|---|

| Sample size: | 300 g |

| Temperature: | 350°C |

| Gas: | Phosphorus trifluoride |

| Pressure: | Atmospheric |

Full scale pilot/demonstration plant

Examples of Test Runs:

| Process | Reduction of mixture of hydroxides |

|---|---|

| Sample size: | 200 Kg |

| Temperature: | 450°C |

| Gas: | Hydrogen/Nitrogen |

| Pressure: | Atmospheric |

| Process | Nickel extraction |

|---|---|

| Temperature: | 50°C |

| Gas: | Carbon monoxide |

| Pressure: | Atmospheric |

| Process | Nickel powder production |

|---|---|

| Temperature: | 350°C |

| Gas: | Carbon monoxide |

| Pressure: | Atmospheric |

Modular Metal Refining Plants, Pilot and Demonstration Facilities

Detailed overview of modular metal refining pilot plants designed for vapour metallurgy, process validation, scale up testing, and production of high quality metal outputs from diverse feedstocks.

Advanced Facilities for Metal Process Development

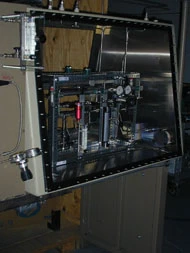

CVMR operates modular metal refining plants ranging from bench scale laboratories to full demonstration facilities. These pilot plants enable controlled testing and validation of metal refining workflows before committing to commercial scale production.

Facilities support evaluation of ore bodies, concentrates, intermediates, scrap materials, and metal bearing waste streams, ensuring technical feasibility and reliable performance data.

Why Modular Metal Refining Plants Are Critical

Modular pilot plants provide the flexibility required to test complex metallurgical processes while minimizing technical and financial risk.

- Multi scale capacity, bench scale grams, intermediate kilograms, and demonstration scale hundreds of kilograms.

- Versatile processing options, roasting, reduction, extraction, refining, powder production, coatings, and net shape creation.

- Automated process control, computer controlled operation with full data tracking.

- Seamless scale up pathways, pilot data directly informs feasibility studies and final plant design.

Bench Scale Pilot Plants

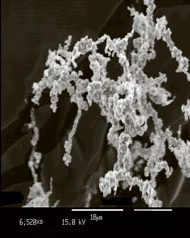

Bench scale systems handle sample sizes from one to ten grams. These fully automated units test roasting, reduction, extraction, and reaction chemistry under tightly controlled temperature, gas, and pressure conditions.

Bench trials allow rapid validation of process viability before advancing to higher throughput testing.

Intermediate Scale Pilot Plants

Intermediate scale units process one to ten kilograms of material per run. These systems support fluid bed or rotational reactors for reduction, extraction, powder decomposition, coating, or net shape formation.

Integrated gas recycling and purification systems ensure safe and environmentally responsible operation while enabling multi step workflows in a single run.

Full Scale Pilot and Demonstration Plants

Demonstration plants process batches from one hundred to one thousand kilograms, supporting complete refining chains from pre treatment through final product generation.

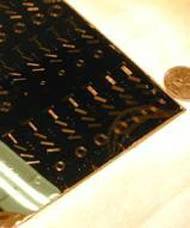

Outputs include metal powders, coatings, net shapes, and refined metals suitable for customer evaluation, qualification testing, or feasibility studies for commercial deployment.

Services Enabled by Pilot Plant Infrastructure

- Ore roasting and pre treatment, to prepare feedstocks for downstream refining.

- Reduction of hydroxides and intermediates, under controlled reaction conditions.

- Metal extraction and purification, from concentrates or contaminated materials.

- Production of powders, coatings, and net shapes, for advanced manufacturing.

- Generation of sample materials and process data, supporting feasibility and scale up planning.

Technology and Process Control

Pilot plants for vapour metallurgy operate with sealed, automated systems that provide precise control over reaction parameters, material purity, and output consistency.

Detailed data logging enables optimization, quality assurance, and reliable projection of commercial scale performance.

From Pilot Testing to Commercial Deployment

Each pilot run generates critical performance data used to design commercial facilities, support investment decisions, and validate process economics.

Modular metal refining plants allow companies to manage risk, refine processes, and confidently transition from laboratory testing to full industrial production.

Applications and Strategic Value

Pilot plant services support projects involving new ore bodies, recycled materials, complex scrap streams, and custom metal production.

Manufacturers gain early access to prototype materials and performance data before committing to large scale capital investment.

Frequently Asked Questions

What materials can be tested in pilot plants

Ore bodies, concentrates, scrap metals, contaminated materials, and industrial residues can be evaluated to validate refining workflows and product quality.

How do pilot plants reduce project risk

Pilot testing provides real world data on yields, purity, and operational stability, reducing uncertainty before commercial scale deployment.

Can pilot plants produce prototype products

Yes, powders, coatings, and shaped metal samples can be produced for evaluation and qualification testing.

Are pilot plant operations environmentally controlled

All systems use sealed processing, gas handling, automation, and safety monitoring to ensure environmental compliance and operator protection.