CVMR Latest News

Understanding the Factors Affecting the Formation of Carbonyl Iron Electrodes in Rechargeable Alkaline Iron Batteries

Aswin K. Manohar, Chenguang Yang, Souradip Malkhandi, Bo Yang, G. K. Surya Prakash and S. R. Narayanan,z Abstract Rechargeable iron-based alkaline batteries such as iron – air and nickel – iron batteries are attractive for large-scale electrical energy storage because iron is inexpensive, globally-abundant and environmentally-friendly. Further, the iron electrode is known for its robustness to repeated charge/discharge cycling. During manufacturing these batteries are charged and discharged 20 to 50 times during which the …

Read More

Feb 12, 2013

•

Corporate Announcements & Growth

•

International Projects & Government Partnerships

•

Refining Manufacturing Technological Development

•

Innovation Research Technology

•

Strategic Partnerships Joint Ventures

•

Recognition Achievements

•

Market Industry Updates

•

Finance Investment Funding

•

Metal Marketing

•

Mining

•

News

•

Technologies

•

Energy

•

Energy

•

3D Printing

•

Newsletter

- Aluminum - $3 125 ▲ 0.86%

- Iron Ore - $100 • 0.00%

- Nickel - $17 894 ▼ 0.02%

- Silver - $90.84 ▲ 4.43%

- Gold - $5 186.50 ▲ 0.89%

- Cobalt - $62 049 • 0.00%

- Copper - $13 189 ▲ 0.89%

- Gallium - $262 585 ▲ 0.10%

- Indium - $646 700 • 0.00%

- Lithium - $23 555 ▲ 6.63%

- Molybdenum - $74 843 • 0.00%

- Neodymium - $166 745 ▲ 0.20%

- Lead - $2 104 • 0.00%

- Palladium - $1 842.22 ▲ 4.08%

- Platinum - $2 297.82 ▲ 5.81%

- Rhodium - $11 750.00 • 0.00%

- Tin - $50 300 ▲ 5.41%

- Tellurium - $110 450 • 0.00%

- Uranium - $196 835 • 0.00%

- Zinc - $3 404 ▲ 1.29%

CVMR News

#Corporate Announcements & Growth, #International Projects & Government Partnerships, #Refining Manufacturing Technological Development, #Innovation Research Technology, #Strategic Partnerships Joint Ventures, #Recognition Achievements, #Market Industry Updates, #Finance Investment Funding, # Metal Marketing, # Mining, # News, # Technologies, # Energy, #Energy, # 3D Printing, # Newsletter

Understanding the Factors Affecting the Formation of Carbonyl Iron Electrodes in Rechargeable Alkaline Iron Batteries

Aswin K. Manohar, Chenguang Yang, Souradip Malkhandi, Bo Yang, G. K. Surya Prakash and S. R. Narayanan,z Abstract Rechargeable iron-based alkaline batteries such as iron – air and nickel – iron batteries are attractive for large-scale electrical energy storage because iron is inexpensive, globally-abundant and environmentally-friendly. Further, the iron electrode is known for its robustness to repeated charge/discharge cycling. During manufacturing these batteries are charged and discharged 20 to 50 times during which the …

Read More

Feb 12, 2013

Carbonyl Surface Coating

Stage 1 A preliminary test applying a carbonyl nickel coating to several substrates was performed at CVMR Corporation in Toronto, Ontario, Canada (see Appendix 1-B in the Introduction Chapter). Zinc alloy A190, copper alloy C110 and low-carbon steel surfaces were prepared by depositing carbonyl nickel at 175 °C (347 °F). The coated specimens were subjected to various thermal exposures to increase interface bonding and to reduce residual stresses. The specimen geometries comprised planchets, approximately …

Read More

Jan 01, 2013

CARBONYL PROCESS

The carbonyl process is not part of the proposed action or any of the alternatives discussed in this EA, but it was briefly investigated during the course of this effort, so a concise summary of the process and the potential environmental impacts are included for reference. The carbonyl process was invented in 1903 and deposits nickel, iron, cobalt and some other metals by a relatively low-temperature gaseous process; but also can extract these metals …

Read More

Jan 01, 2013

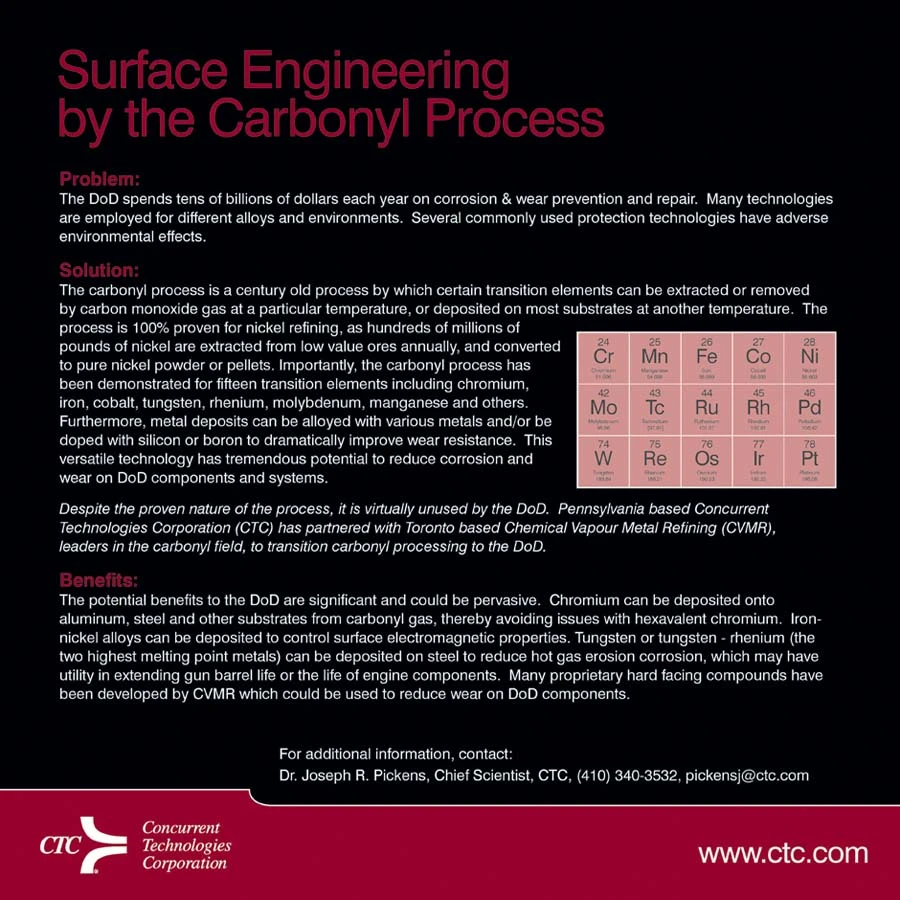

Surface Engineering by the Carbonyl Process

Problem: The DoD spends tens of billions of dollars each year on corrosion & wear prevention and repair. Many technologies are employed for different alloys and environments. Several commonly used protection technologies have adverse environmental effects. Solution: The carbonyl process is a century old process by which certain transition elements can be extracted or removed by carbon monoxide gas at a particular temperature, or deposited on most substrates at another temperature. The process is …

Read More

Sep 19, 2012

CVMR CARBONYL PROCESS Application to Laterite Ore of a CVMR client in Africa

CVMR’s process for refining of Ferralite and Saprolite ore maximizes value of the ores by producing value added products. Ferralite ore A typical Ferralite ore contains 40-45% of Iron, 1-1.5% of Nickel, 0.04-0.10% of Co (potentially Copper, PGE and Rare earth elements). * Published with permission of the client.

Read More

Sep 03, 2012